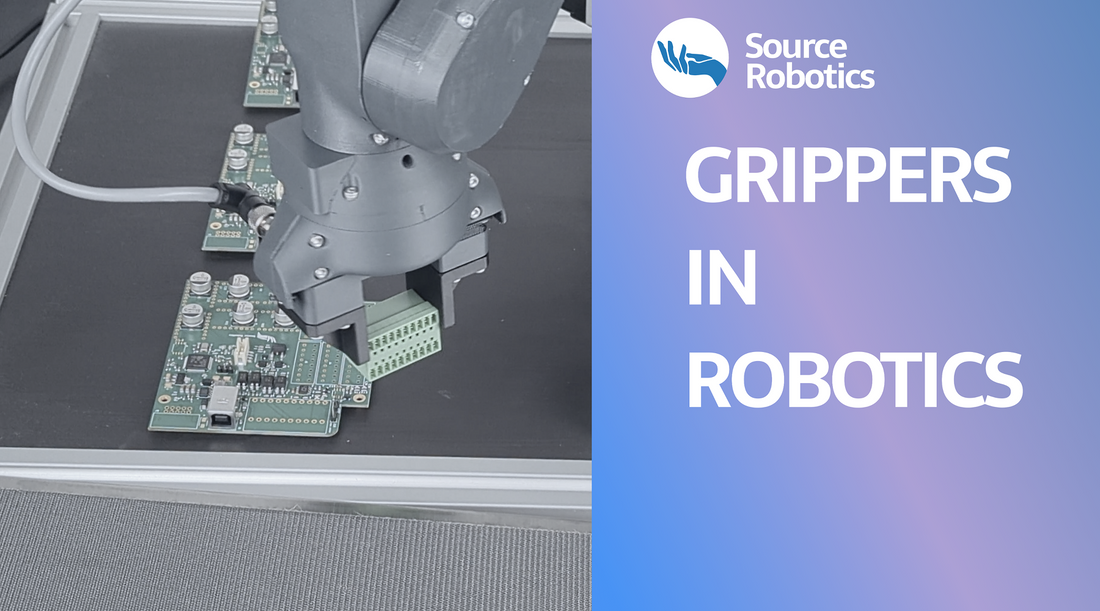

What are grippers?

Grippers are devices designed to enable robots to grasp and manipulate objects. Similar to human hands, grippers are positioned at the end of a robot arm, allowing them to pick up and hold items. They combine the strength of the arm with the dexterity needed to handle various objects. Grippers play a crucial role in material handling with collaborative robots (cobots), facilitating tasks such as stacking large boxes or manipulating small, delicate electronic components.

Pneumatic gripper

One of the primary advantages of pneumatic grippers is their ability to deliver substantial gripping force while remaining compact, lightweight, and cost-effective. In manufacturing environments where space is limited, pneumatic grippers emerge as an economical and ergonomic choice. Their compact design is particularly advantageous for end-of-arm tooling, as it helps to keep the overall mass low.

Moreover, pneumatic grippers are known for their ease of maintenance. Once installed and operational, they can withstand millions of cycles without requiring frequent maintenance interventions. This reliability is invaluable in high-volume production settings where downtime must be minimized.

Given their ease of application and widespread adoption, pneumatic grippers dominate the market. The prevalence of compressed air systems in manufacturing facilities further contributes to their appeal, as integrating pneumatic grippers typically requires minimal effort and cost, leveraging existing infrastructure efficiently.

Electric gripper

SSG-48 adaptive electric gripper

Electric grippers, also known as servo-electric grippers, offer distinct advantages, particularly in cleanroom operations where the absence of dirt or particulate matter is crucial, especially when handling dust-sensitive products like circuit boards. These grippers provide finer control, enabling precise measurements of parts to ensure correct size and shape, particularly useful when dealing with microprocessors. In mere microseconds, electric grippers can assess if a part meets specifications, preventing premature release.

One notable advantage of utilizing electric grippers is the ability to precisely control both the closing speed and the grip force. This level of control is achievable due to the direct proportionality between the current of the electric motor and the torque it applies. This capability proves particularly beneficial in numerous scenarios, particularly when the gripper is tasked with handling delicate or fragile objects. The ability to tailor the closing speed and grip force enhances the gripper's versatility, ensuring gentle yet secure manipulation of items, thus minimizing the risk of damage or breakage.

However, electric grippers come with some drawbacks. They tend to be slightly larger due to the incorporation of motors and typically offer less gripping force compared to pneumatic counterparts. Additionally, electric grippers generally entail higher costs. Installation of electric grippers also requires PLC controllers or PC, adding to the overall cost and necessitating a certain level of expertise for deployment in production environments.

Vaccum gripper

Vacuum grippers represent a versatile type of end effector utilized in robotic palletizing, a process crucial for stacking and organizing products on pallets for transportation or storage. They leverage suction to lift and manipulate various objects, including boxes, display boxes, cartons, and packed products, without the need for gripping from the sides or below. This lifting method allows for even distribution of the payload across the object's surface, preventing deformation or damage. Customizable in design, vacuum grippers can accommodate different object sizes and shapes by adjusting the number and position of suction cups or valves.

Energy-efficient and noise-reducing, vacuum grippers utilize self-closing valves that activate only when necessary, contributing to operational efficiency. Consisting of an electrical or venturi vacuum pump connected to a vacuum head with suction cups or a foam pad, these grippers find applications in industries such as manufacturing, warehousing, and logistics. Particularly advantageous for handling delicate or irregularly shaped objects, vacuum grippers excel where traditional mechanical grippers may fall short.

However, vacuum grippers do have limitations. They require a certain level of airtight seal, making them less effective on very porous or rough surfaces. Objects with irregular or curved surfaces may necessitate specialized gripper designs or multiple suction cups to ensure a reliable grip. Despite these constraints, vacuum grippers remain a valuable asset in material handling processes, offering flexibility and efficiency in a variety of applications.

End effectors

End effectors serve as vital components of robotic systems, being devices affixed to the end of a robot's arm to facilitate interaction with the surrounding environment. These mechanisms play a fundamental role in handling, manipulating, and sensing objects, essentially serving as the primary means through which robots engage with their surroundings to perform various tasks. Customizable to specific applications, end effectors are versatile and can be tailored to execute a broad spectrum of functions, including gripping, cutting, welding, painting, and more.

From welding and gluing to paste dispensing and cutting, end effectors encompass a wide array of process tools essential for diverse industrial operations. Moreover, they can incorporate sensors, cameras, ultrasound, and other sensing technologies to enhance functionality and enable advanced applications. By directly integrating with the workpiece, end effectors serve as the interface through which robots execute tasks, exerting a significant influence on overall productivity.

While grippers represent a common type of end effector, the category encompasses various other devices. For instance, a smart camera mounted on the end of a robot arm aids in inspection tasks, while a welding tool end effector enables the safe automation of welding processes when attached to a collaborative robot (cobot).

How to choose the right gripper / end effector.

Several factors should be considered when selecting a gripper for your application, and these factors will depend on various aspects of your process. Here are some questions that can help guide your decision:

- Available Resources: Do you have access to air compressors, vacuum pumps, or other necessary equipment to power the gripper?

- Product Fragility: Is the product you handle fragile or delicate, requiring gentle handling to prevent damage?

- Maintenance Requirements: How much service are you willing to perform on the gripper? Do you need a low-maintenance solution?

- Environmental Conditions: Will the gripper be operating in a cleanroom environment where cleanliness is essential? Does it need to meet specific IP protection ratings?

- Payload Capacity: What is the maximum payload you will need the gripper to handle?

- Force Feedback: Do you require force feedback capabilities to ensure precise gripping and handling of objects?

- Item Shape and Type: What shapes and types of items will the gripper be handling? Are they uniform or irregularly shaped? Are they food products, raw materials, or something else?

Considering these factors will help you make an informed decision when choosing the right gripper for your application, ensuring optimal performance and efficiency in your processes.